Acetate Sunglasses,Built for Premium and Growing Brands

Material depth. Stable structure. Refined finishing — engineered for reliable sampling and scalable, repeatable production.

You don't need a finalized design to start a conversation — many projects begin at the concept stage.

What Is Acetate?

Acetate is a plant-based sheet material used in premium eyewear.

Unlike standard plastics, it is layered, cut, tumbled, and polished for depth and tactility.

The result: richer color, smoother touch, and a more elevated finish.

This is often the stage where brands compare acetate with injection or metal based on positioning and long-term feel.

Acetate vs Other Materials

Choose materials based on brand positioning, design intent, and wear expectations.

| Feature | Acetate | Injection (TR/PC) | Metal |

|---|---|---|---|

| Look & Feel | Rich, layered depth | Consistent, smooth | Sleek, minimal |

| Color Expression | High depth, custom tones | Wide range, solid | Limited, surface finish |

| Design Complexity | High freedom | Moderate | Precision required |

| Weight Profile | Medium, optimizable | Lightweight | Light to medium |

| Ideal Price Tier | Premium to luxury | Entry to mid | Mid to premium |

In practice, many brands decide based on brand positioning first, then adjust material details accordingly.

How Quality Acetate Sunglasses Are Made

Producing acetate sunglasses involves over 100 individual processes. Below are six core stages where craftsmanship, consistency, and long-term durability are defined.

Acetate Selection

Color, pattern, and thickness are selected to match design intent while meeting structural and performance requirements.

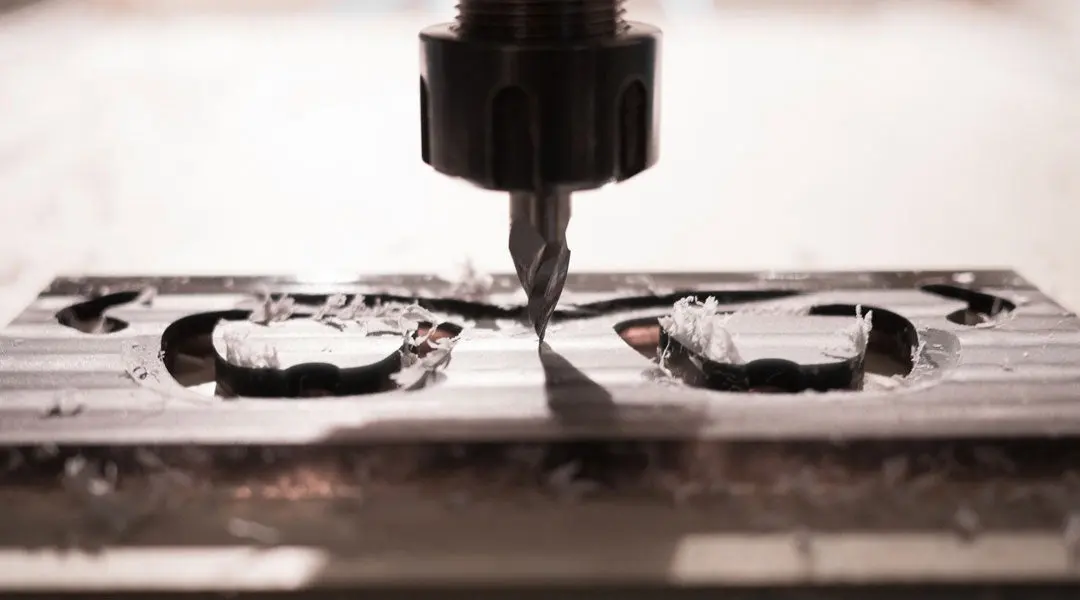

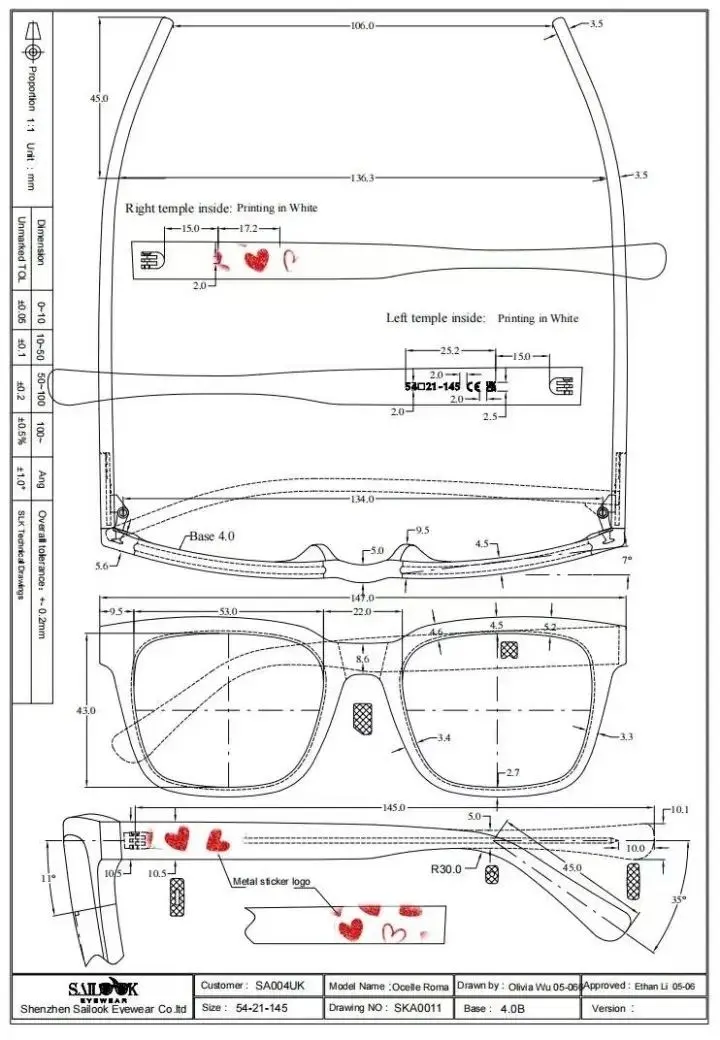

CNC Cutting

Precision CNC cutting of fronts and temples ensures dimensional accuracy and repeatability across production runs.

Forming & Fitting

Controlled heat forming and pre-assembly fitting ensure consistent shape, long-term comfort, and frame alignment.

Tumbling

Progressive tumbling smooths edges, refines contours, and prepares surfaces for final finishing and uniform surface texture.

Hand Polishing

Hand polishing enhances depth, gloss, and tactile quality, defining the visual and tactile character of premium acetate frames.

Assembly & Inspection

Hardware assembly, alignment verification, and final inspection ensure each frame meets functional and aesthetic standards.

Many brands reach out to us at this stage to validate feasibility before moving into sampling.

Representative Acetate Sunglasses Projects

Examples shown for reference only.

Thick-cut acetate with stable geometry and long-term shape retention.

Layered construction showcasing depth, texture, and refined transitions.

A silhouette developed to express brand identity — balanced with manufacturability.

Engineered thickness distribution for comfort without losing visual presence.

If your concept feels similar in complexity or intent, it's usually worth a quick feasibility discussion.

Color & Texture That Feels Different

Acetate's depth comes from layered sheets and polishing — not surface coating.

Ideal for tortoise tones, transparent hues, and signature brand palettes.

Who This Is For

Established Eyewear Brands

Premium lines that demand stable QC and repeatability.

Fashion & Lifestyle Brands

Extending into eyewear with strong design language.

Independent / Designer Brands

Small-batch development with professional engineering support.

If you don't fit perfectly into one category, that's common — many projects sit between these stages.

Customization Options

- Frame: shape, thickness, bevels, temple details

- Color: sheet sourcing, custom tones, layered patterns

- Lenses: UV400, polarized, gradient, mirror options

- Branding: laser, foil, metal logo, temple core, hinge marks

- Packaging: cases, cleaning cloth, retail-ready sets

Projects often start with just one or two defined elements, with details refined as development progresses.

Engineering & Sampling That Brands Can Trust

- DFM review to reduce risk before tooling and sampling

- Controlled sample-to-production consistency

- Fit, alignment, and hinge performance evaluation

- Clear iteration loop with documented changes

Quality & Compliance Support

Built for export markets with documented QC processes and material traceability.

We support target-market compliance needs (e.g., CE/FDA-ready documentation where applicable).

We usually flag relevant compliance requirements early, based on your target market.

MOQ & Project Timeline

Start small, scale with confidence.

Inquiry & NDA

(optional)

Design & DFM

Engineering review

Sampling

Prototype development

Pilot Run

Pre-production testing

Mass Production

Full-scale manufacturing

MOQ and lead time vary by design complexity and component selection.

These steps are a general reference — timelines and MOQs are often adjusted based on project needs.

Why Sailook

- Repeatable quality you can scale

- Reliable capacity and lead-time control

- Strong engineering for deep customization

- Material know-how and compliance awareness

- Fast, clear communication and project management

- Confidentiality and IP protection mindset

- Long-term responsibility after delivery

FAQ

These questions often come up during early-stage acetate sunglasses development.

Acetate does not have to feel heavy.

Through thickness distribution, frame geometry, and structural design, weight can be optimized while maintaining visual presence and durability.

Yes. Acetate colors can be customized based on sheet availability.

Options range from classic tortoise and solid tones to transparent hues and layered patterns, depending on material sourcing and production feasibility.

We offer a wide range of lens options including UV400, polarized, gradient, mirror, and specialty treatments.

Lens selection is typically aligned with your brand positioning, usage scenario, and target market.

We ensure consistency by documenting all approved changes, controlling key dimensions, and conducting alignment and assembly checks at each stage.

This helps ensure that mass production accurately reflects the approved sample in fit, finish, and structure.

MOQ depends on design complexity and component selection.

Some projects begin at a smaller scale and are structured to scale as the collection develops.

Yes. We support branded packaging solutions including cases, cleaning cloths, and retail-ready sets.

Packaging is typically developed to align with your brand identity, positioning, and retail requirements.

Get in Touch

Ready to Build Your Acetate Sunglasses Line?

Tell us your concept, target market, and quantity range — we'll reply with a practical development plan.