INJECTION / PLASTIC OPTICAL FRAMES

Injection Optical Frames Engineered for Prescription Accuracy & Long-Term Stability

Precision-molded optical frames built for dimensional repeatability, stable lens mounting, and scalable prescription programs.

This Page Is for You If:

You operate prescription-driven optical programs

Batch consistency matters more than seasonal design changes

You need predictable lens fitting across long-term supply

You're planning controlled volumes, not one-off styles

If not, explore our Acetate Optical Frames or TR90 Optical Frames instead.

Overview

What Injection Optical Frames Are Built For

Injection optical frames are produced through precision molding processes that emphasize dimensional repeatability and structural reliability.

Rather than focusing on material texture, these frames are selected for prescription programs where lens fit accuracy, batch consistency, and predictable production are essential.

They are commonly used in long-running optical collections that prioritize stability over seasonal variation.

Advantages

Advantages for Prescription-Focused Programs

Dimensional Consistency

Mold-controlled geometry supports reliable lens installation across batches.

Stable Frame Structure

Designed to maintain shape during daily wear and routine handling.

Production Predictability

Injection processes support clear timelines and repeatable outcomes.

Program-Level Cost Control

Suitable for long-term optical lines with planned volumes.

Material Comparison

Injection Optical Frames Compared to Other Materials

Material selection in optical frames should follow prescription demands and supply expectations.

| Feature | Injection Plastic | TR90 | Acetate | Metal |

|---|---|---|---|---|

| Lens mounting stability | High | Medium | Medium | High |

| Shape repeatability | High | Medium | Medium | Medium |

| Flexibility | Low–Medium | High | Medium | Low |

| Visual emphasis | Clean and uniform | Minimal and functional | Textured and expressive | Defined and structural |

| Typical use | Long-term prescription programs | Comfort-driven optical wear | Lifestyle optical collections | Classic optical frames |

Important Considerations

Who Injection Optical Frames Are NOT For

Injection optical frames are not designed for every optical concept. We recommend alternative materials when flexibility, handcrafted aesthetics, or frequent design changes are the priority.

Brands focused on seasonal fashion drops or rapid design turnover

Collections emphasizing handmade textures or acetate layering

Programs requiring frequent structural revisions after launch

If long-term dimensional stability, prescription accuracy, and batch consistency are not your core requirements, other materials may be more suitable — and we'll advise honestly before production.

Optical Fit

Optical Fit Built on Dimensional Accuracy

Prescription reliability depends on frame geometry that remains stable before and after lens installation.

Lens rim dimensions planned for consistent mounting

Frame rigidity supports prescription accuracy

Bridge geometry maintains alignment under load

Reduced risk of post-assembly distortion

Designed to minimize refitting and remakes

Wear Comfort

Everyday Wear with Structural Confidence

Comfort in injection optical frames comes from predictable balance rather than flexibility.

A stable structure helps frames sit consistently throughout the day, supporting users in school, work, and daily routines.

This makes injection frames a practical choice for frequent, long-hour wear.

Balanced front-to-temple weight

Stable positioning during daily movement

Suitable for repeated on/off use

Engineering

Tooling & Engineering That Support Prescription Accuracy

Injection optical frames rely on tooling precision and structural planning to deliver consistent outcomes.

Mold design aligned with optical fit targets

Wall thickness planning for rim stability

Bridge and hinge interface consistency

Multi-cavity control for batch uniformity

Documented tolerances for repeat production

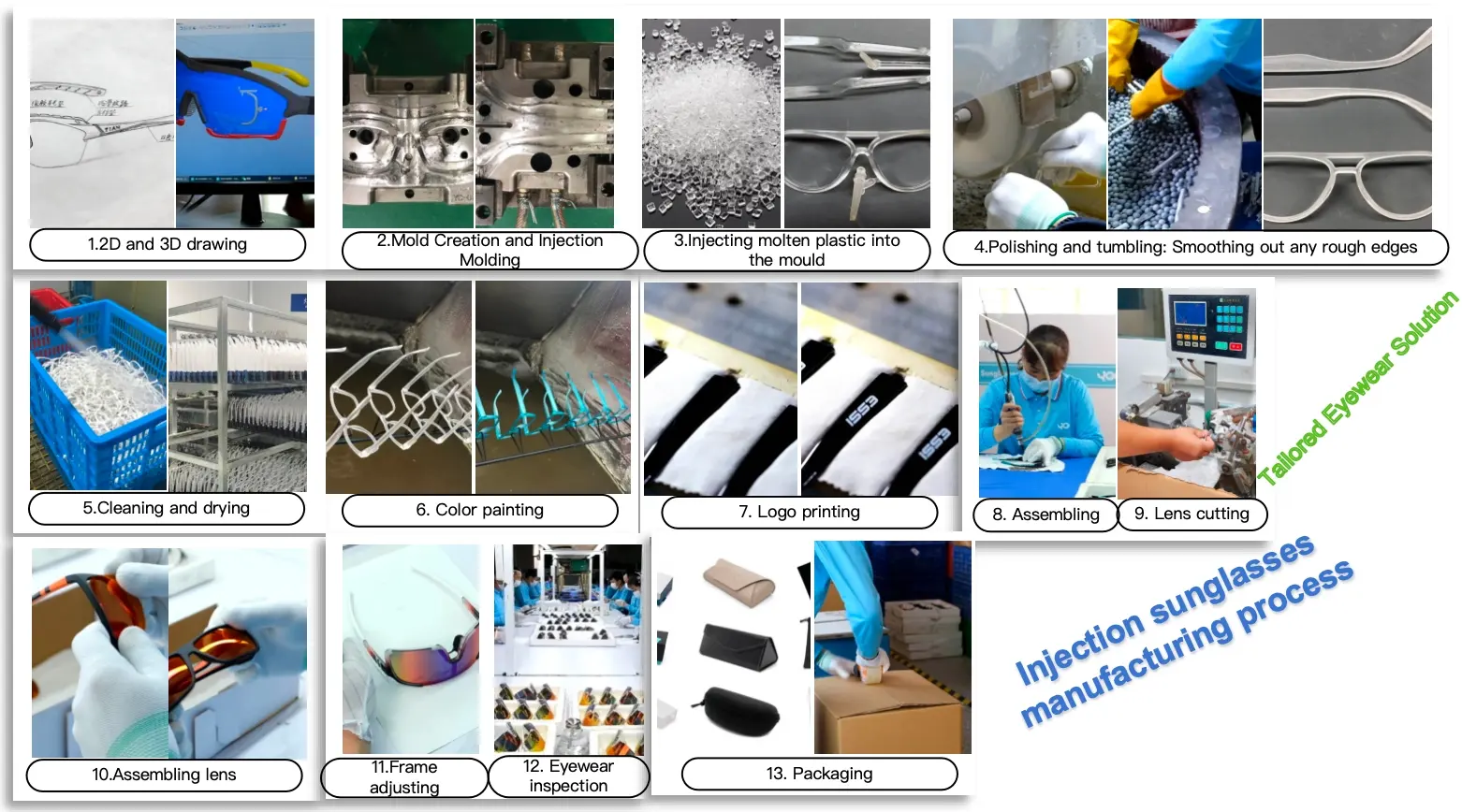

Production Process

Manufacturing Process Overview

2D and 3D Drawing

Mold Creation and Injection Molding

Injecting Molten Plastic into the Mould

Polishing and Tumbling

Cleaning and Drying

Color Painting

Logo Printing

Assembling

Lens Cutting

Tooling complexity and color programs influence timelines.

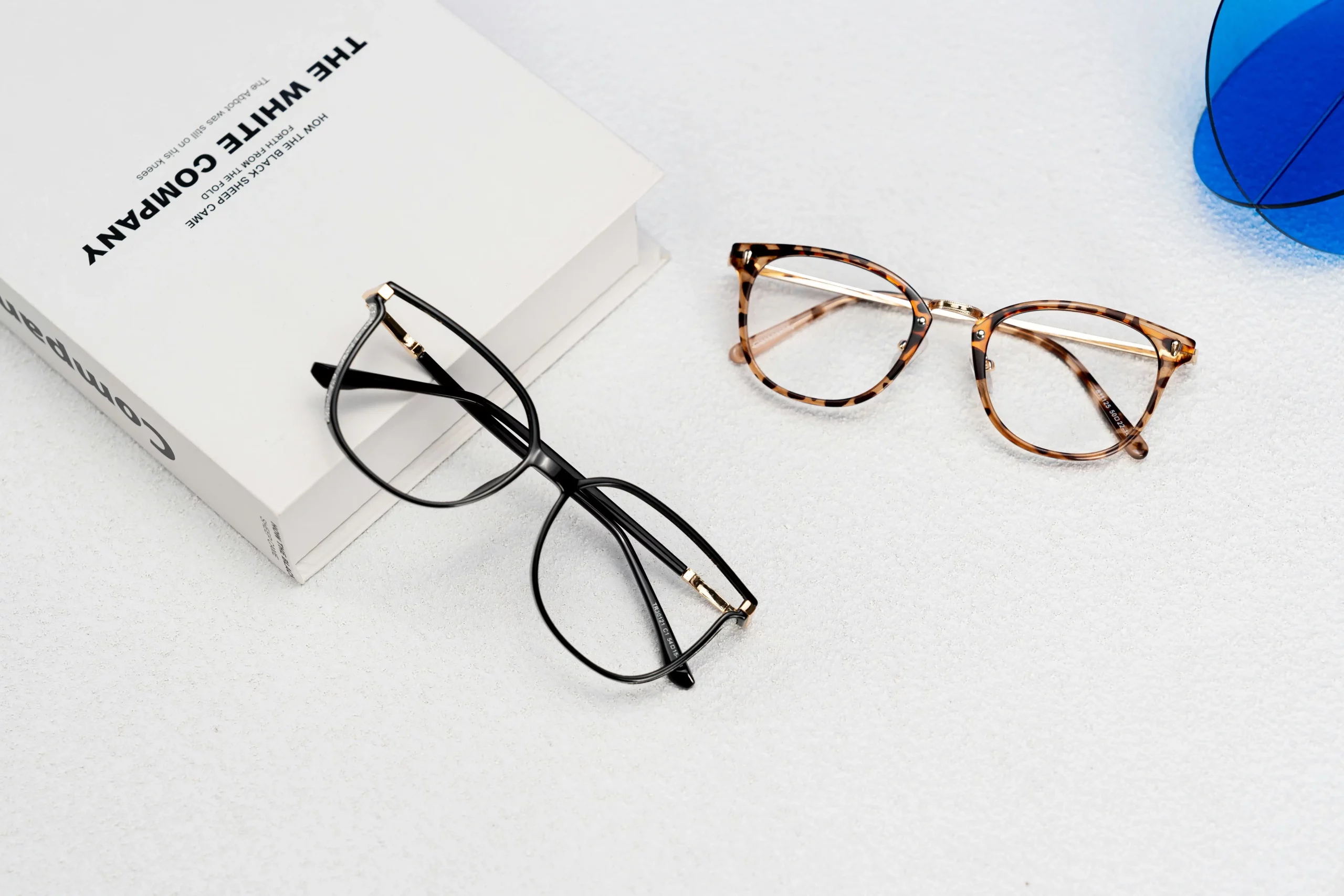

Representative Projects

Representative Injection Optical Frame Projects

Examples shown for capability reference only.

Student Prescription Frame

Designed for daily wear and high handling frequency.

Commercial Optical Program Frame

Built for stable long-term supply.

Minimal Injection Optical Frame

Clean geometry focused on fit consistency.

Color-Series Optical Frame

One structure developed for multi-color programs.

Customization

Customization Within a Scalable Structure

Injection optical frames allow controlled customization without disrupting production stability.

Frame shape and size

Lens rim thickness

Bridge width and geometry

Color and surface finish

Branding details and packaging

Risk Management

First Order Risk Control for Injection Optical Programs

Injection optical frames require early structural decisions. Our role is to help brands minimize first-order risk before tooling investment.

Pre-tooling feasibility review

Evaluate lens type, prescription range, and structural tolerance before mold development.

Dimensional validation in sampling

Technical drawings and tolerance review before physical samples are approved.

Controlled pilot quantities

Pilot runs to validate assembly, fit, and batch stability before scale-up.

Clear tooling ownership & lifecycle planning

Tooling designed for long-term programs, not short-term cost cutting.

This approach allows brands to launch injection optical frames with confidence — not guesswork.

Supply Stability

Supply Stability for Long-Term Optical Programs

Injection optical frames are frequently chosen for programs that demand consistent supply over time.

Batch-to-batch dimensional control

Measurements monitored to reduce variation.

Assembly repeatability

Interfaces designed for consistent feel.

Long-run SKU support

Structures suitable for extended product life cycles.

Program documentation

Changes tracked to protect optical fit integrity.

Common Questions

FAQ

Yes. They are commonly selected for programs requiring stable lens mounting and dimensional control.

Injection frames emphasize stability and consistency; TR90 emphasizes flexibility and comfort.

Tooling-based processes support high repeatability when tolerances are managed.

We conduct tolerance review and dimensional validation during sampling to reduce post-tooling risk. If adjustments are required, they are addressed before mass production.

Tooling requirements, color programs, and production scale.

Yes. They are often used for extended-life optical SKUs.

Get Started

Planning an Injection Optical Frames Program?

Share your target users, prescription requirements, and expected volume — we'll help evaluate tooling, structure, and production feasibility.

Whether you're developing a new optical collection or scaling an existing prescription program, our team is ready to support your injection optical frames development.

Frames only. Lenses are not included.