METAL OPTICAL FRAMES

Metal Optical Frames Engineered for Reliable Daily Wear

Structural clarity, controlled adjustability, and production-ready consistency for prescription eyewear programs.

First Order Risk Control for Metal Optical Frames

Designed to reduce uncertainty before committing to production.

For first-time metal optical frame projects, risk usually comes from unclear structure, unstable fitting behavior, or inconsistency between samples and bulk production.

Our development process is structured to minimize those risks before you commit to volume.

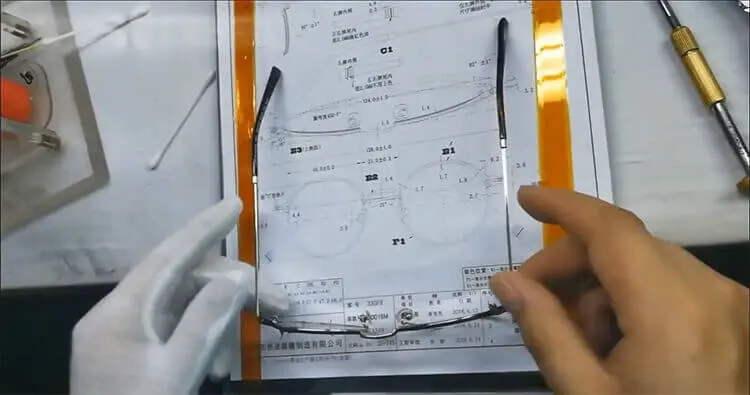

- Sample-to-bulk geometry locking Frame structure, bridge angles, and hinge tension are defined at sampling stage and controlled through production.

- Controlled adjustment tolerance Metal elasticity and adjustment range are engineered for repeated optician fitting, not one-time wear.

- Production repeatability planning Material thickness, joining methods, and surface finish are selected based on long-term consistency — not just sample appearance.

- Transparent feasibility evaluation If a design is better suited for titanium or acetate, we advise before tooling, not after.

You Scale

What Defines Metal Optical Frames

Metal optical frames are commonly selected for their structural clarity and predictable fitting behavior. Rather than pursuing extreme lightness, these frames prioritize stability, alignment, and practical adjustability for prescription wear. Metal optical frames are chosen not for extremes, but for predictability — in fitting, adjustment, and long-term wear.

They are widely used in everyday optical programs where consistency and long-term usability matter.

Practical Advantages of Metal Optical Frames

Structurally Stable Lens Support

Frame geometry designed to maintain alignment after lens installation and daily adjustment.

Consistent design language

Defined metal lines create clean silhouettes across classic and modern styles.

Reduced after-sales adjustments

Suitable for routine use, frequent handling, and long-term programs.

Predictable cost & supply planning

A balanced solution for brands planning consistent supply and cost control.

Metal vs Titanium Optical Frames

Different metals serve different collection strategies.

| Standard Metal | Titanium | |

|---|---|---|

| Design focus | Structure and visual clarity | Lightweight refinement |

| Adjustability | Practical and flexible | Controlled and precise |

| Weight perception | Balanced | Very light |

| Cost positioning | Mid-range | Premium |

| Typical use | Everyday optical collections | High-end optical programs |

Optical Fit Built Around Stability

Prescription frames must hold shape, support lenses securely, and allow practical adjustment over time. Our focus is fit consistency — not just initial appearance.

- Rim geometry planned for prescription lens mounting

- Bridge structure supporting even nose load

- Temple opening angle and tension control

- Left-right symmetry and alignment checks

- Designed for repeatable fitting, not one-off samples

Comfort Through Balance, Not Extremes

Comfort in metal optical frames comes from balanced weight distribution and controlled contact points. Rather than pursuing ultra-light construction, we focus on stability that supports long wear without constant readjustment.

Engineering for Consistent Structure

Metal optical frames require thoughtful planning to maintain geometry from sampling to mass production. Our engineering approach emphasizes repeatability and controlled assembly.

- Structural rigidity planning for optical use

- Hinge integration with stable open-close feel

- Bridge and rim reinforcement where needed

- Assembly alignment control to reduce variation

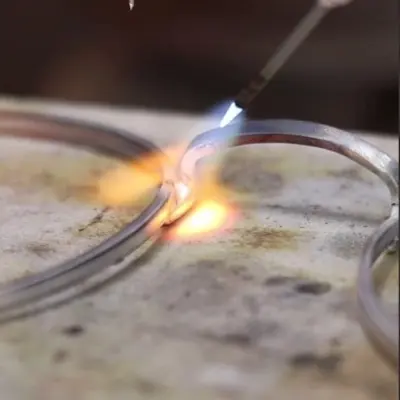

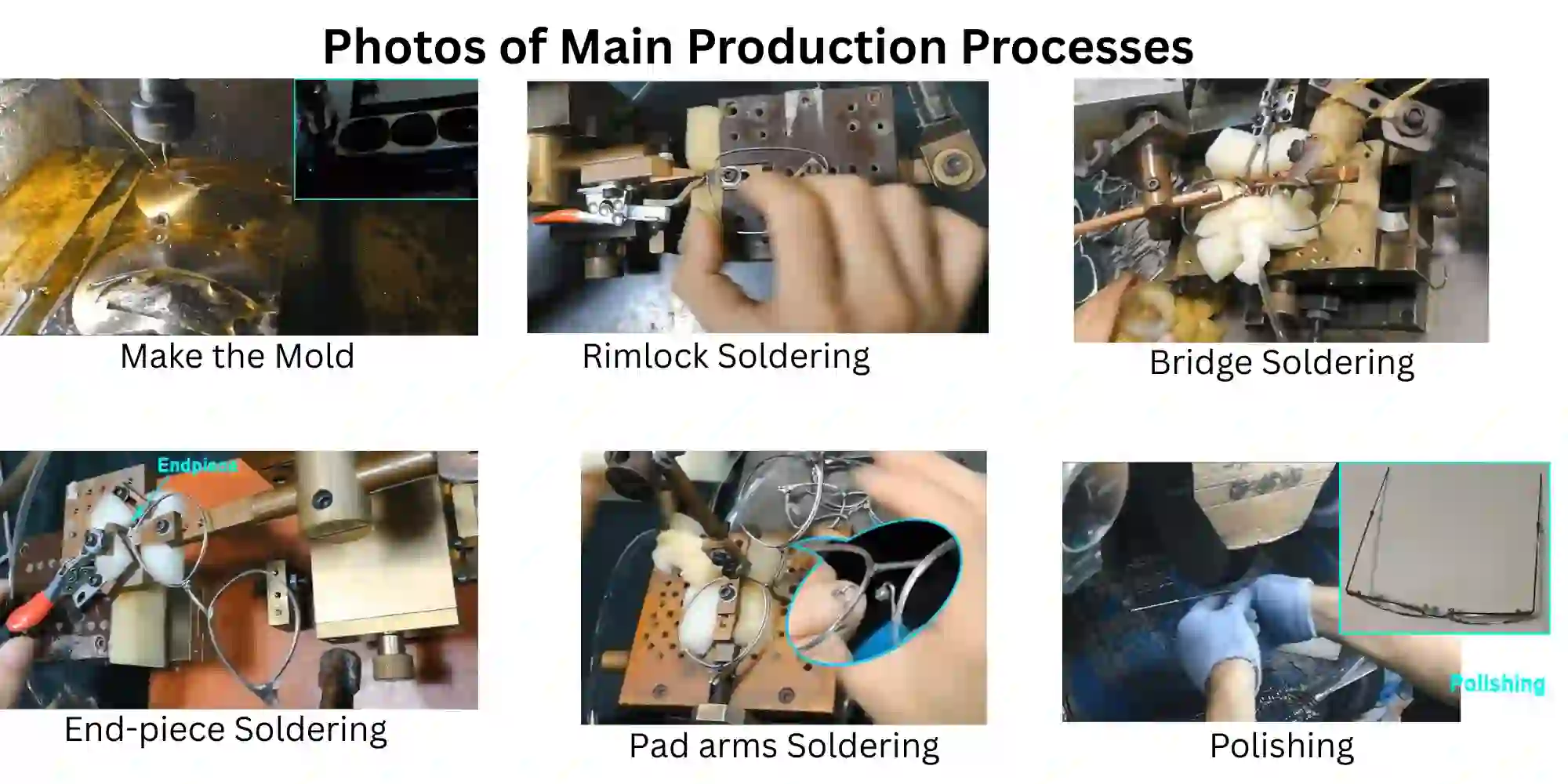

Manufacturing Process Overview

Actual process steps may vary depending on structure and finish requirements.

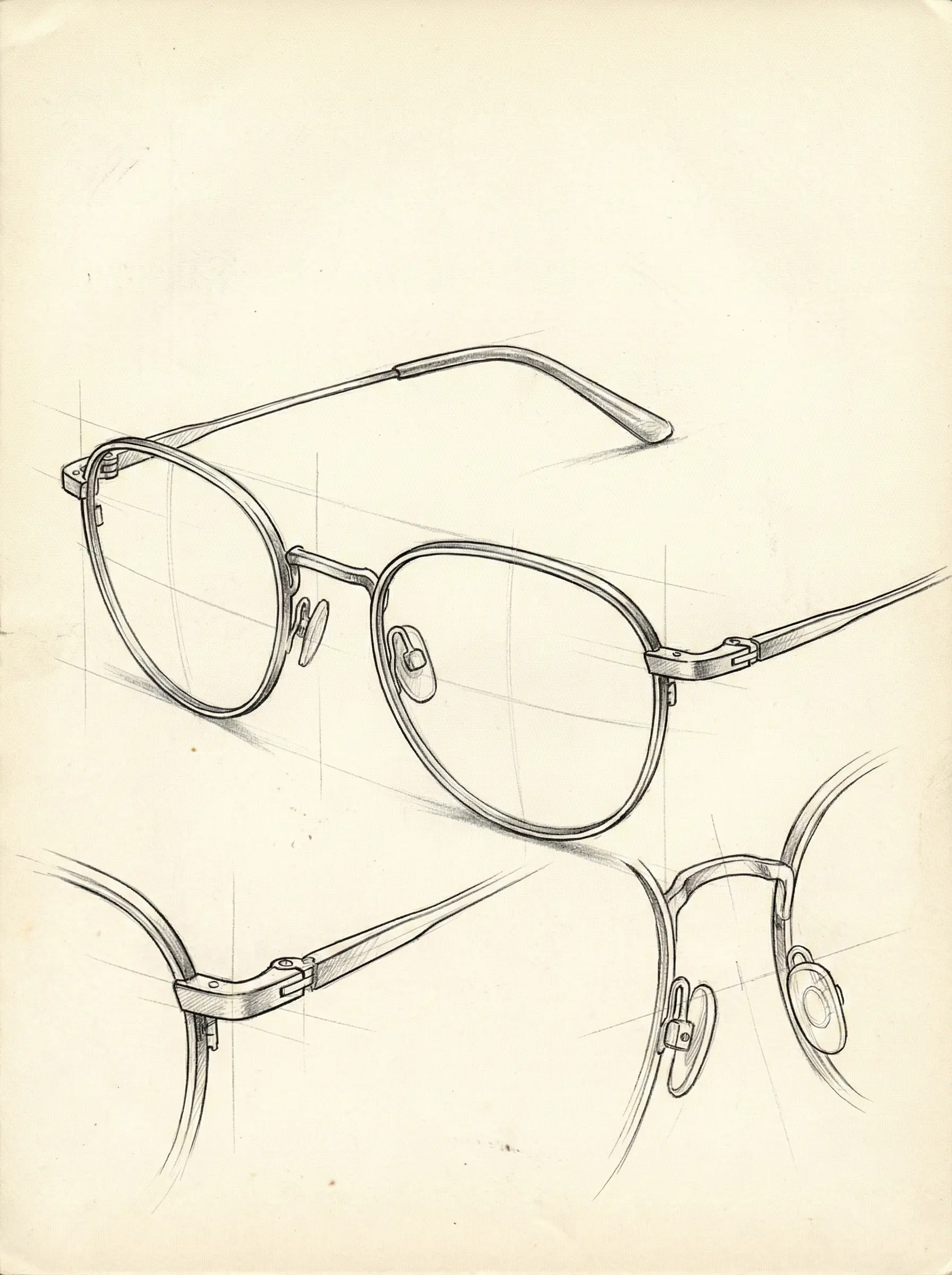

Representative Metal Optical Frame Concepts

Examples shown for capability reference only.

Thin Metal Daily Frame

Clean structure designed for everyday prescription wear.

Structural Metal Optical Frame

Reinforced geometry for stable lens support.

Classic Minimal Metal Frame

Timeless design with controlled proportions.

Hybrid Metal Optical Frame

Metal structure combined with complementary materials.

Customization Options

Metal optical frames can be tailored to match different markets and brand identities.

- Frame shape and sizing

- Bridge geometry and width

- Temple length and curvature

- Metal thickness and profile

- Surface finish and color treatment

- Branding details and packaging support

Quality & Production Readiness

We emphasize structural inspection, alignment consistency, and finish durability for optical programs. Our quality focus supports long-term collections rather than short-term samples.

FAQ

Yes. They are commonly used for everyday prescription frames due to stable structure and adjustability.

Metal frames allow practical adjustment when geometry and hinge design are planned correctly.

We focus on symmetry, alignment checks, and controlled assembly.

Yes. Geometry, finish, and details can be adapted to market positioning.

Design complexity, finishing, and component selection.

Planning a Metal Optical Frames Collection?

Share your design direction, target market, and expected volume. We’ll help evaluate structure, fitting behavior, and production feasibility — before you commit.