METAL SUNGLASSES

Custom Metal Sunglasses ManufacturingEngineered for Independent Brands & Scalable Collections

Metal sunglasses engineered for stability, fit accuracy, and consistent assembly — built to scale, not just to sample.

OEM & ODM metal eyewear manufacturing focused on structural control, production repeatability, and export-ready quality.

When to Choose Metal Sunglasses?

Metal sunglasses are ideal when your collection requires:

— Defined silhouettes with clear structural lines

— Controlled geometry that stays consistent in bulk production

— A balanced cost structure for fashion or lifestyle collections

Compared with titanium, standard metal frames offer greater design freedom and more accessible cost positioning — making them especially suitable for scalable, market-driven projects.

Is Metal Right for Your Project?

Metal sunglasses are a strong choice if you are:

— Launching a fashion or lifestyle brand

— Planning mid-range pricing with consistent quality

— Looking for stable structure rather than ultra-lightweight performance

If your priority is extreme lightness or technical performance, titanium may be a better option.

Key Advantages of Metal Sunglasses

Strong Visual Structure

Clean metal lines create defined silhouettes and a confident design language.

Design Versatility

Flexible design directions — from thin profiles to bold structural looks.

Reliable Daily Durability

Engineered for stable wear and everyday handling across seasons.

Balanced Cost & Performance

A practical choice for scalable collections without sacrificing finish quality.

Metal vs Titanium Sunglasses

Titanium is often chosen for premium lightweight performance. Metal frames are chosen for visual expression and commercial balance.

| Standard Metal | Titanium | |

|---|---|---|

| Typical feel | Solid, structured presence | Lightweight, refined |

| Weight focus | Balanced | Very light |

| Design expression | Wide range (thin to bold) | Minimal to premium-technical |

| Cost positioning | Mid | Premium |

| Best for | Fashion & lifestyle scalability | Premium performance collections |

Design Possibilities with Metal Frames

Metal frames are often selected for their line clarity and the freedom to explore shape language without relying on thick material volume.

Engineering for Structure and Stability

A great metal sunglasses design must hold its geometry, feel stable on the face, and remain consistent in production. We focus on structural planning and assembly control — so the design stays reliable beyond the sample stage.

Comfort Designed into the Structure

Metal sunglasses can feel comfortable when weight distribution and fit points are planned from the start. We tune balance, temple tension, and contact areas to support stable wear — without over-promising "extreme lightness."

Balanced weight distribution

Stable fit under movement

Smooth hinge feel and comfortable contact points

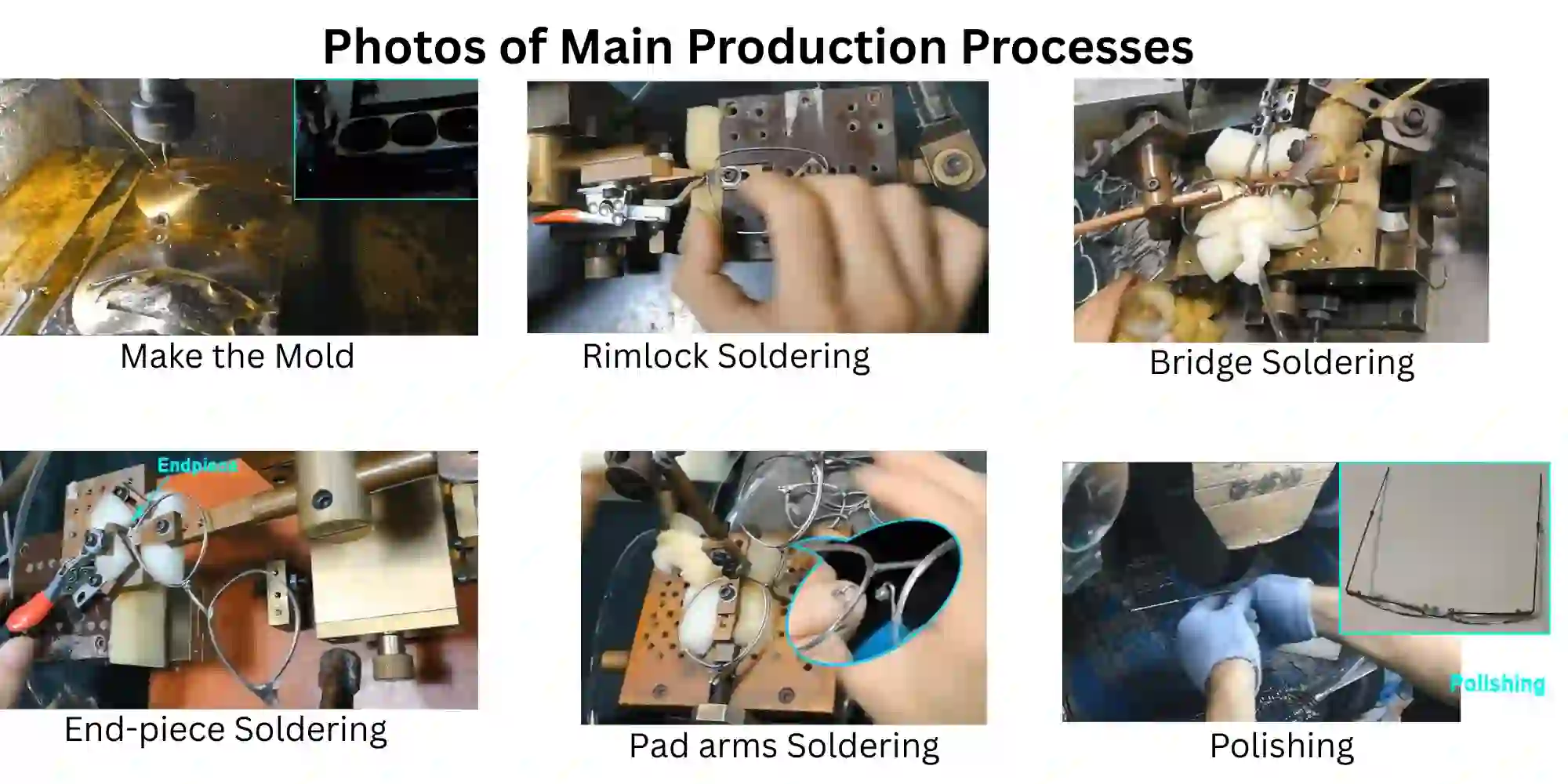

How Metal Sunglasses Are Made

Material Selection & Planning

Forming & Shaping

Joining & Structural Assembly

Surface Finishing & Color Treatment

Final Assembly & Fit Tuning

Quality Inspection

Steps vary by structure, finishing, and component selection.

Typical timeline: Sampling: 20–30 working days | Bulk production: 45–65 working days after sample approval

Representative Metal Sunglasses Projects

Examples shown for reference only.

Classic Thin-Metal Sunglasses

Clean lines with an understated silhouette for modern collections.

Bold Metal Structure Design

Strong visual presence with stable geometry and defined edges.

Geometric Fashion Metal Sunglasses

Shape-forward design built for commercial scalability.

Hybrid Metal Sunglasses

Metal structure combined with complementary materials for balance and style.

Customization Options for Metal Sunglasses

Match design direction and market positioning through controlled geometry, finishing, and brand details.

Once your direction is defined, we'll translate it into technical drawings, sampling plans, and a clear cost structure.

Quality & Compliance Support

We support structural inspection, finishing consistency, and quality processes aligned with export sunglasses programs. Our focus is stable geometry, consistent assembly, and clear documentation for scalable collections.

We focus on consistency from first sample to bulk shipment — minimizing surprises after approval.

FAQ

Frequently Asked Questions — Everything brands need to know before starting metal sunglasses production.

Yes. A large portion of our clients are independent brands, designers, and first-time eyewear founders.

We support projects from early concept and sampling through controlled first production runs, helping brands validate the market before scaling.

Our standard MOQ is typically 300–500 pcs per model, depending on structure and finishing.

For first-time cooperation, we're open to discussing feasible starting options to balance cost, risk, and scalability.

Not necessarily.

We carefully control material thickness and structural balance to ensure metal frames remain lightweight and comfortable for daily wear, without compromising strength.

Yes. Metal frames allow for precise adjustments at the nose pads, temples, and overall fit, which helps improve comfort and wearability across different face shapes.

Metal frames offer a refined, structured look at a more accessible cost, while titanium is lighter, more corrosion-resistant, and positioned at a higher price tier.

We help clients choose the best material based on brand positioning, budget, and target market.

We offer a wide range of finishes, including matte, polished, brushed, electroplating, PVD coating, and custom color treatments — allowing brands to achieve anything from minimal to statement designs.

We follow a multi-stage quality control system covering material inspection, in-process checks, and final inspection.

This ensures stable quality, consistent finishing, and reliable results from samples through bulk production.

Planning a Metal Sunglasses Collection?

You don't need a full plan yet, just tell us what you're thinking. Reference images, ideas, materials, or target market are all helpful — we'll respond with a practical development plan.