TITANIUM OPTICAL FRAMES

Titanium Optical Frames Engineered for Daily Comfort & Production Stability

Lightweight strength, controlled geometry, and repeatable finishing — built for prescription-ready optical collections, from sampling to scale.

Engineering Approach

First-Order Risk Control for Titanium Optical Frames

Titanium frames are unforgiving.

We reduce first-order risk through controlled sampling, geometry checks, and repeatable engineering.

Titanium optical frames leave little room for error. Small deviations in geometry, joining, or surface treatment can lead to instability, poor fit, or production inconsistency.

That's why our titanium projects always start with risk control — not mass production.

Before any bulk order, we help brands:

Validate comfort and balance through engineering-led sampling

Lock key dimensions and symmetry before production

Identify potential failure points early (hinges, bridges, joins)

Ensure sample-to-production repeatability

This approach helps independent brands avoid costly rework, unstable collections, and delayed launches.

Why Titanium for Optical Frames

Titanium is a premium metal known for its strength-to-weight advantage and corrosion resistance.

For optical frames, it supports daily wear comfort while maintaining structural stability for consistent fitting.

Ideal for brands building long-term collections where feel, durability, and refined design matter.

Key Benefits of Titanium Optical Frames

All-day Lightweight Comfort

Reduced weight helps minimize pressure during extended wear.

Long-term Shape Stability

Designed to stay stable through daily handling and adjustment.

Corrosion Resistance

Reliable performance in humid, coastal, and high-sweat environments.

Premium Metal Aesthetic

Clean lines and refined finishes suited for premium optical collections.

Titanium vs Other Optical Frame Materials

Material choice directly affects comfort, adjustability, and long-term fitting performance.

For brands building premium optical collections, titanium offers the most stable balance.

| Feature | Titanium | Stainless Steel | Acetate | TR90 |

|---|---|---|---|---|

| Long-wear comfort | Excellent | Good | Good | Good |

| Adjustability | Good | Good | Excellent | Limited |

| Structural stability (fitting) | Excellent | Good | Good | Good |

| Corrosion resistance | Excellent | Good | Excellent | Excellent |

| Typical positioning | Premium | Mid | Mid–Premium | Value–Mid |

Optical Fit & Geometry That Stay Consistent

Optical frames must feel comfortable and remain stable after lens fitting and daily wear. We focus on geometry and alignment — so comfort and fit are repeatable, not accidental.

Rim geometry and lens-fit readiness

Bridge design and nose-load balance

Temple tension, opening angle, and overall balance

Left-right symmetry and alignment control

Designed for adjustment without unwanted deformation

Comfort Brands Can Stand Behind

Lightweight titanium frames help reduce pressure on the nose and ears, supporting all-day wear.

Balanced geometry and a stable hinge feel contribute to a comfortable experience throughout the day.

Balanced weight distribution

Stable fit under movement

Refined, durable feel

Engineering Considerations for Titanium Optical Frames

Titanium requires thoughtful engineering to balance strength, flexibility, comfort, and finishing durability. Our goal is repeatable outcomes — from sampling to scaled production.

Precision forming and shaping for consistent geometry

Controlled joining methods for structural integrity

Stable hinge performance designed for daily adjustment

Finishing built for long-term aesthetics and wear resistance

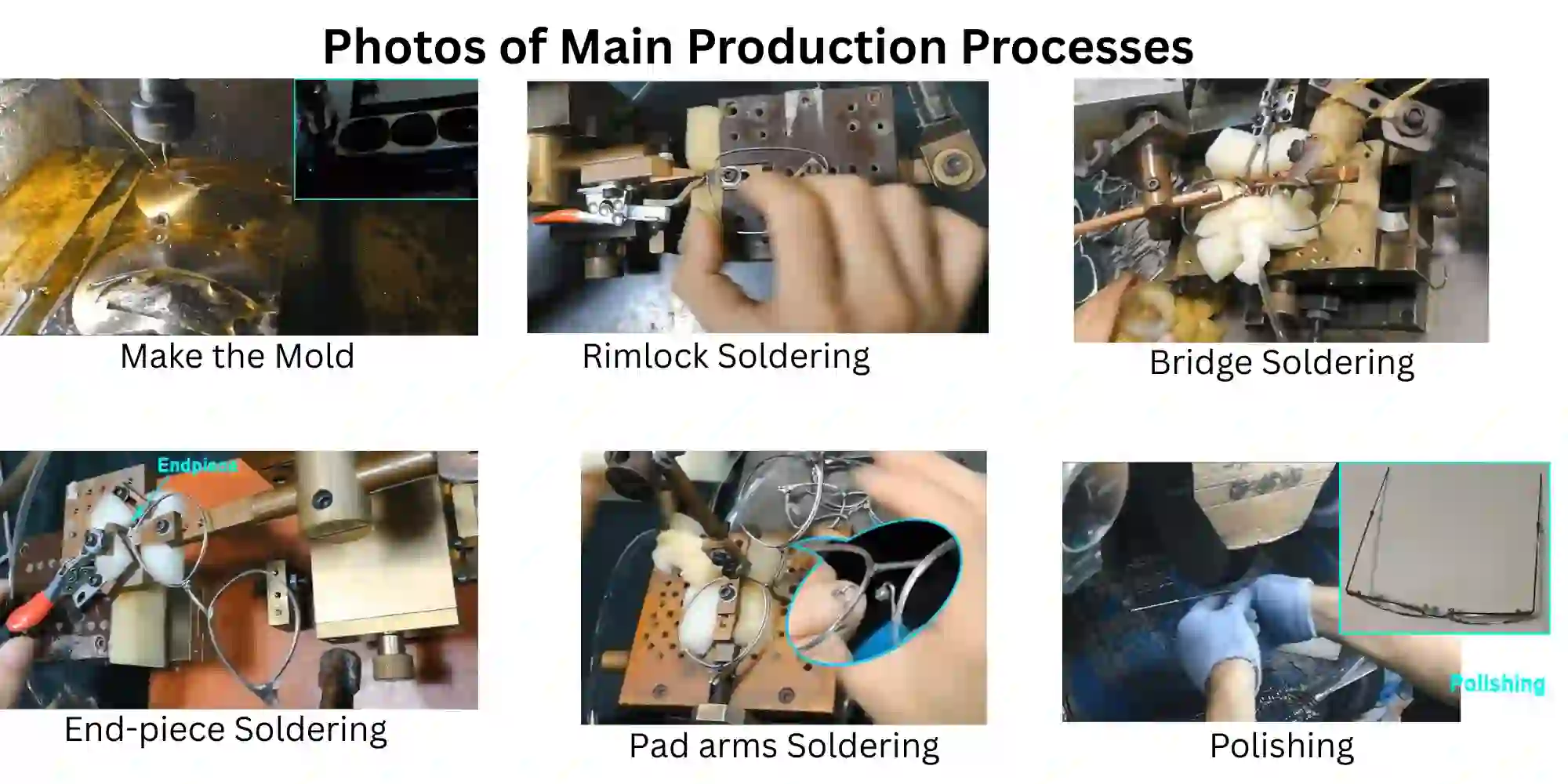

Manufacturing Process

How Titanium Optical Frames Are Made

Material Specification & Planning

Precision Cutting & Forming

Joining & Structural Assembly

Surface Treatment & Finishing

Assembly, Alignment & Tuning

Quality Inspection

Steps may vary based on design complexity, finish, and components.

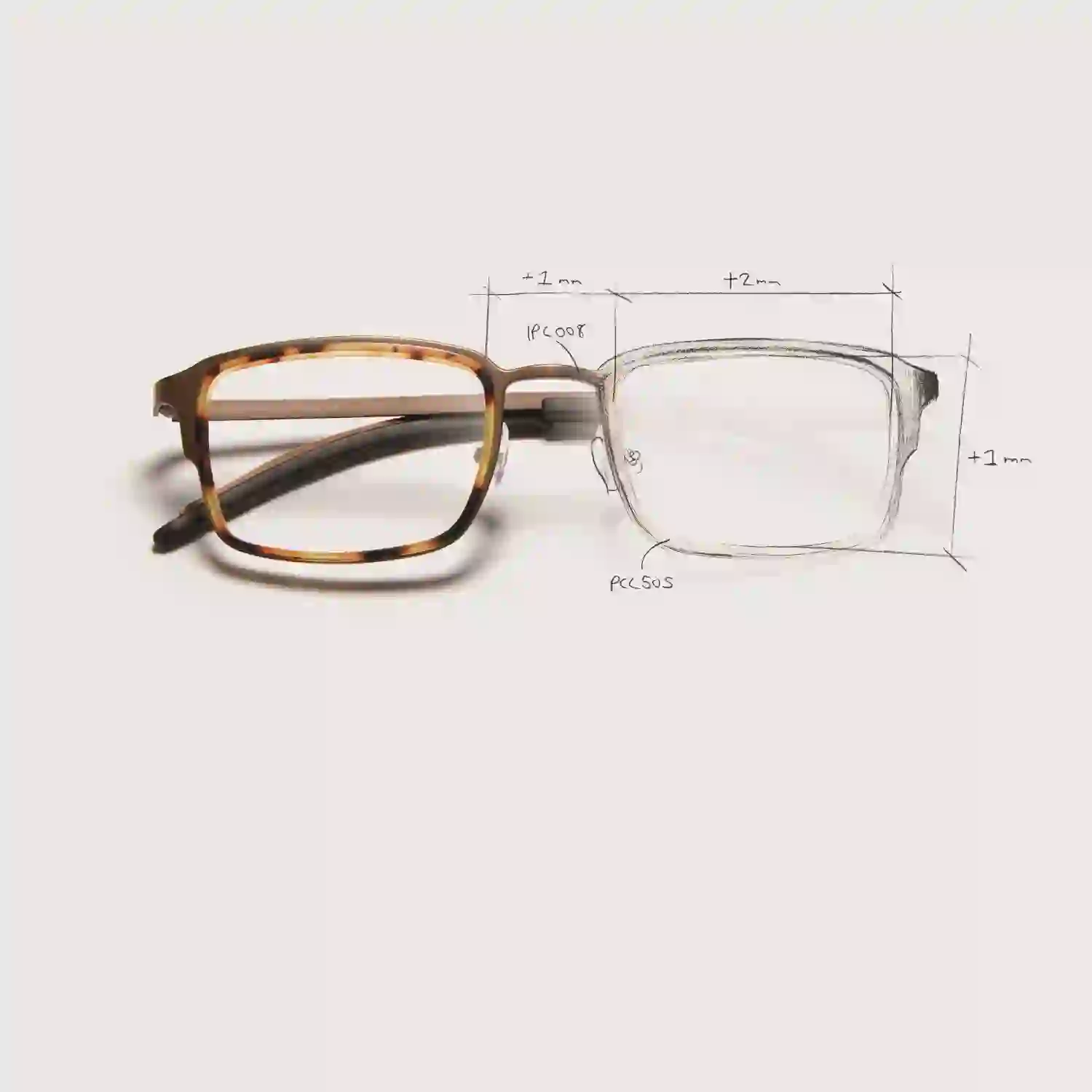

Representative Titanium Optical Frames Projects

Examples shown for reference only.

Ultra-light Daily Wear Frame

Built for comfort-first collections with stable geometry.

Structural Rim Design

Developed for consistent fitting and long-term stability.

Minimal Premium Titanium Frame

Clean lines and refined finishing for elevated positioning.

Hybrid Titanium Design

Titanium structure combined with complementary materials for balance and style.

Customization Options for Titanium Optical Frames

Customize geometry, finishing, and brand details to match your collection goals.

Frame shape, sizing, and profile

Bridge width and geometry options

Temple length, curvature, and fit tuning

Surface finish (matte, brushed, polished)

Branding details and signature elements

Packaging and presentation options

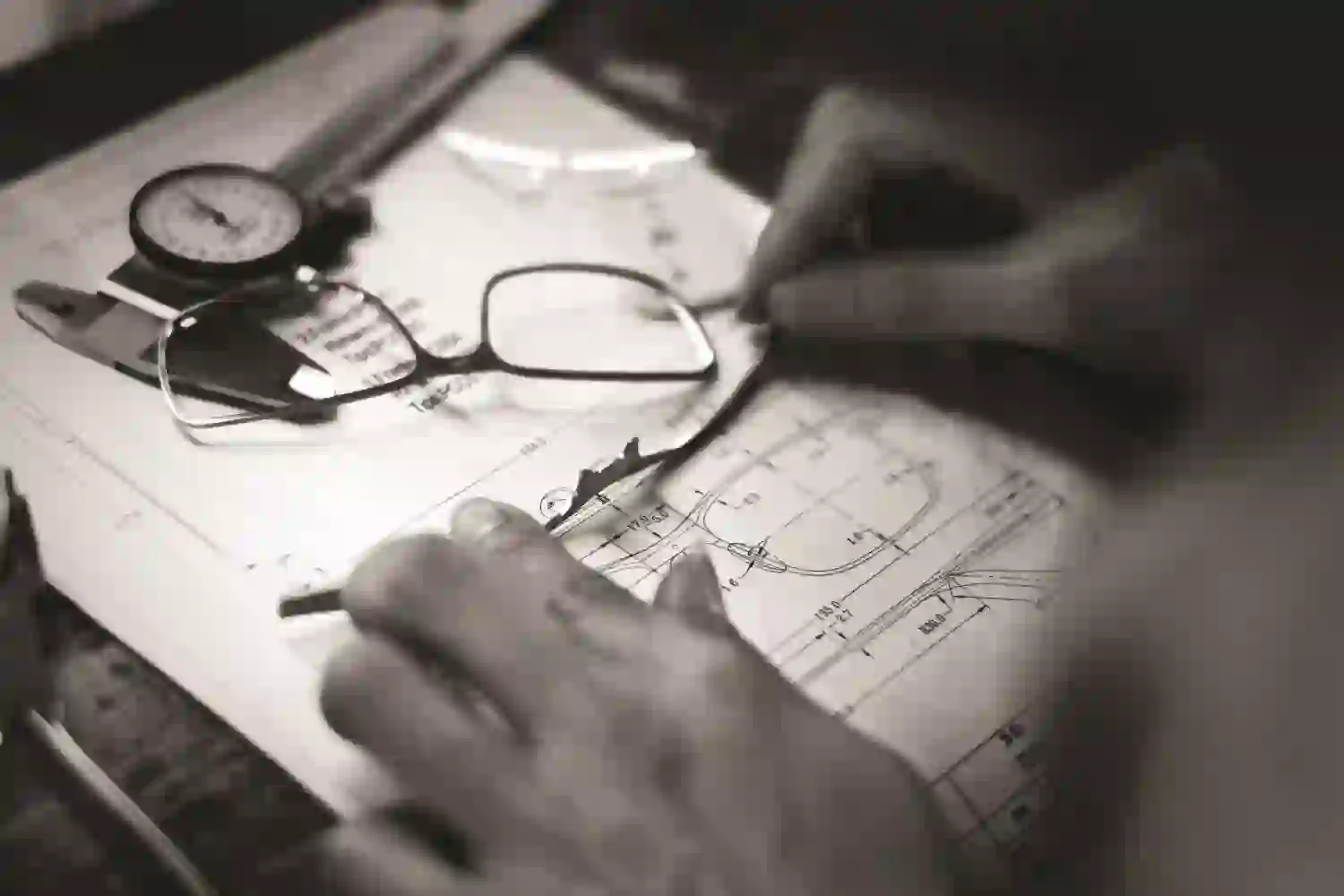

Sampling & Development Support That Prevents Costly Mistakes

Most titanium frame problems don’t come from production — they come from insufficient development.

Optical DFM feedback before tooling decisions

Practical structure suggestions aligned with optical fit requirements.

Symmetry and alignment checks at drawing and sample stages

Geometry reviewed to improve consistency across production.

Iteration tracking to avoid undocumented changes

Changes documented and communicated across sample stages.

Sample-to-production controls to reduce variance

Key interfaces and dimensions controlled to reduce variation.

Our goal is simple: help you move from "great sample" to "stable production" without surprises.

Quality & Compliance Support

We support material traceability, structural inspection, and quality processes aligned with export optical markets. Our approach emphasizes stable fitting, consistent finishing, and clear documentation for long-term collections.

FAQ

Yes. Titanium frames can be adjusted for fit, though the material requires careful handling to avoid work-hardening or deformation.

Titanium's lightweight nature helps reduce pressure points when geometry and balance are well designed.

We inspect alignment during assembly and tune fit to reduce variation across production.

Yes. Bridge geometry, temple length/curvature, and fit tuning can be developed to match your target users.

Structure complexity, finishing requirements, and component selection are the main factors.

Get Started

Ready to Develop a Titanium Optical Frame — Without Guesswork?

Share your concept, target market, and quantity range. Even if you’re early-stage, we’ll help you evaluate feasibility before committing.