TITANIUM SUNGLASSES

Titanium Sunglasses Engineered for Lightweight Strength

Premium titanium construction delivering strength, corrosion resistance, and all-day comfort — built for elevated sunglasses collections.

Commonly chosen for brands prioritizing lightweight comfort, durability, and refined metal aesthetics.

Why Titanium for Sunglasses

Titanium is a premium metal valued for its strength-to-weight ratio and corrosion resistance.

In sunglasses, it allows for lightweight structures without compromising durability or long-term stability.

It is commonly chosen by brands focused on performance, longevity, and refined minimal aesthetics, especially when wear comfort matters more than initial material cost.

Key Benefits of Titanium Sunglasses

Lightweight Comfort

Reduced weight helps minimize pressure during extended wear.

High Strength & Durability

Strong yet tuned for everyday resilience and long-term shape stability.

Corrosion Resistance

Reliable performance in humid, coastal, and outdoor environments.

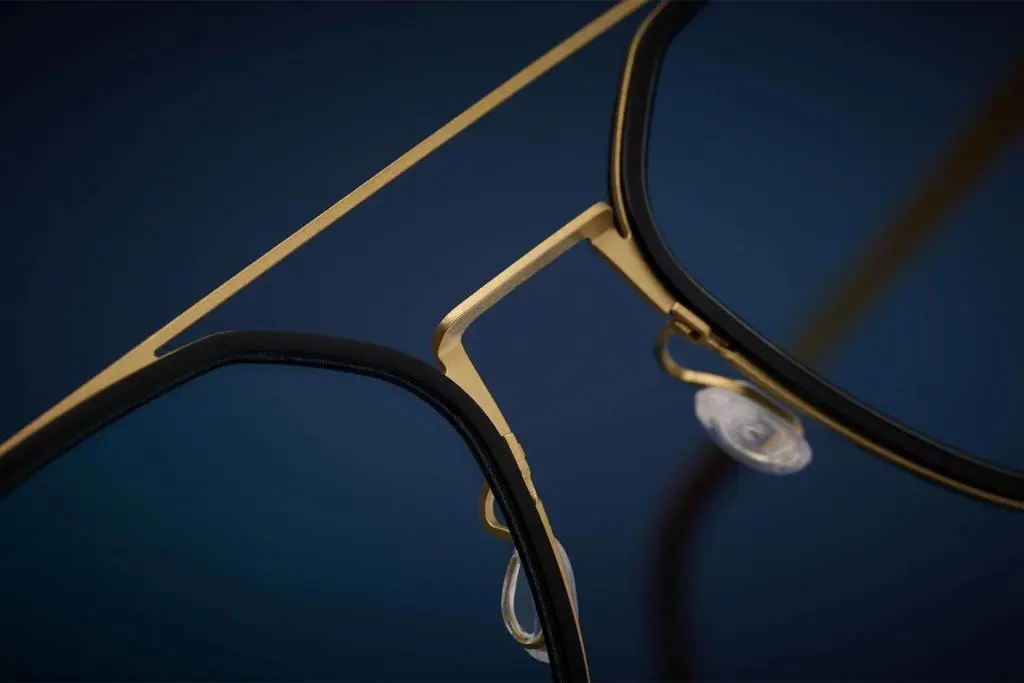

Premium Metal Aesthetic

Clean lines and refined finishes suited for high-end collections.

These advantages are especially relevant for premium, performance, and lifestyle collections designed for daily or extended wear.

Titanium Compared to Other Metals

Material selection should align with brand positioning and wear expectations.

| Property | Titanium | Stainless Steel | Aluminum |

|---|---|---|---|

| Weight | Very light | Moderate | Light |

| Strength | High | Medium | Medium |

| Corrosion Resistance | Excellent | Good | Fair |

| Comfort for Long Wear | Excellent | Moderate | Good |

| Typical Positioning | Premium | Mid | Mid |

In practice, titanium is rarely chosen for entry-level collections, but favored when comfort, longevity, and brand perception are key considerations.

Engineering Considerations for Titanium Sunglasses

Titanium frames require more precise engineering than standard metal frames to balance rigidity, flexibility, and long-term wear comfort.

Achieving this balance depends on controlled forming, stable joining, and consistent dimensional accuracy throughout production.

Our engineering approach focuses on structural reliability, stable fitting, and repeatable production outcomes.

- Precision forming and shaping of titanium components

- Controlled joining methods for structural integrity

- Balanced rigidity and flexibility for daily use

- Surface finishing designed for durability and aesthetics

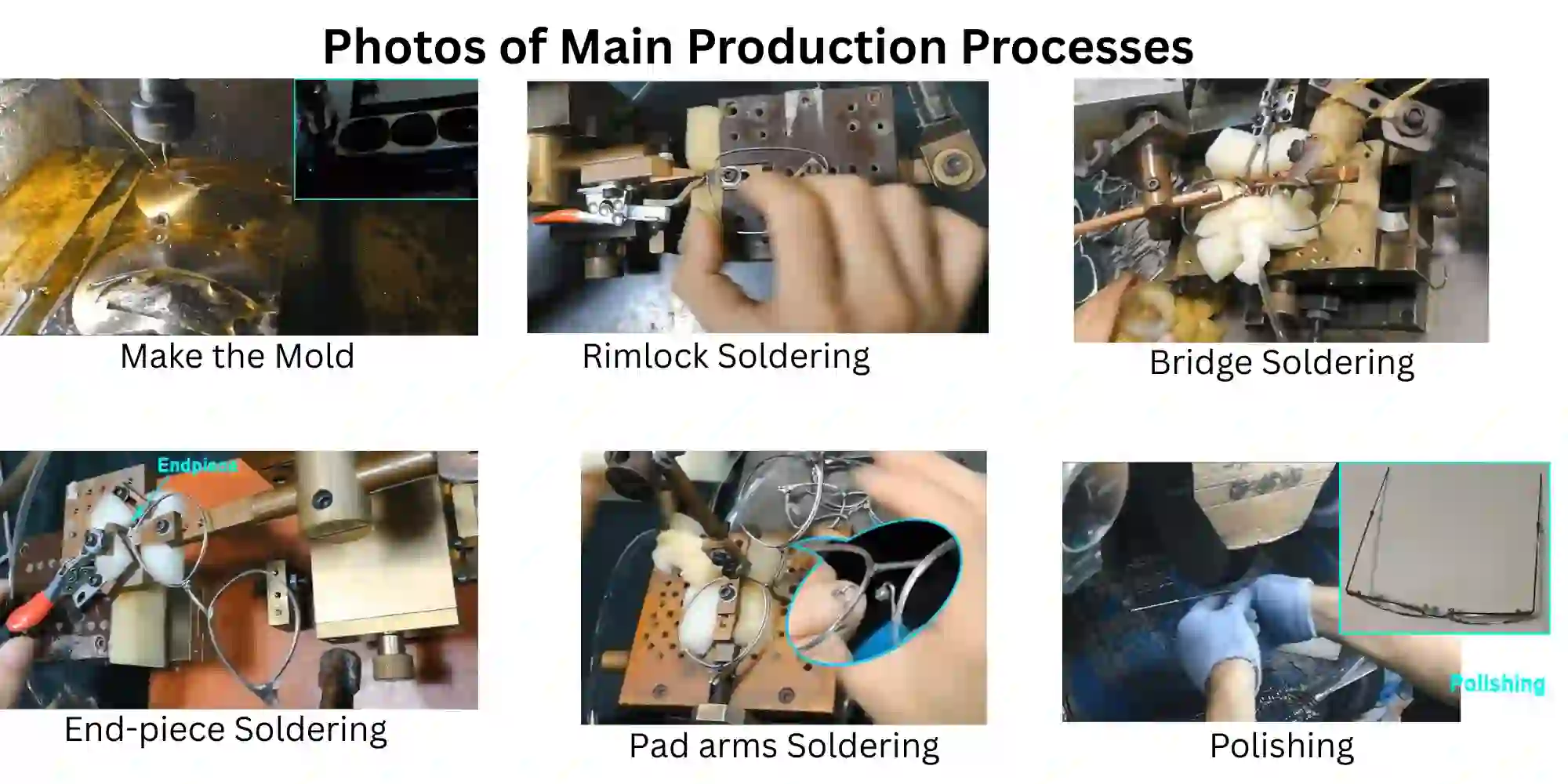

How Titanium Sunglasses Are Made

Material Selection & Specification

Precision Cutting and Forming

Joining & Structural Assembly

Surface Treatment & Finishing

Final Assembly & Alignment

Quality Inspection

Process may vary based on structure, finishing, and component selection.

Many brands reach out to us at this stage to evaluate feasibility before moving into sampling.

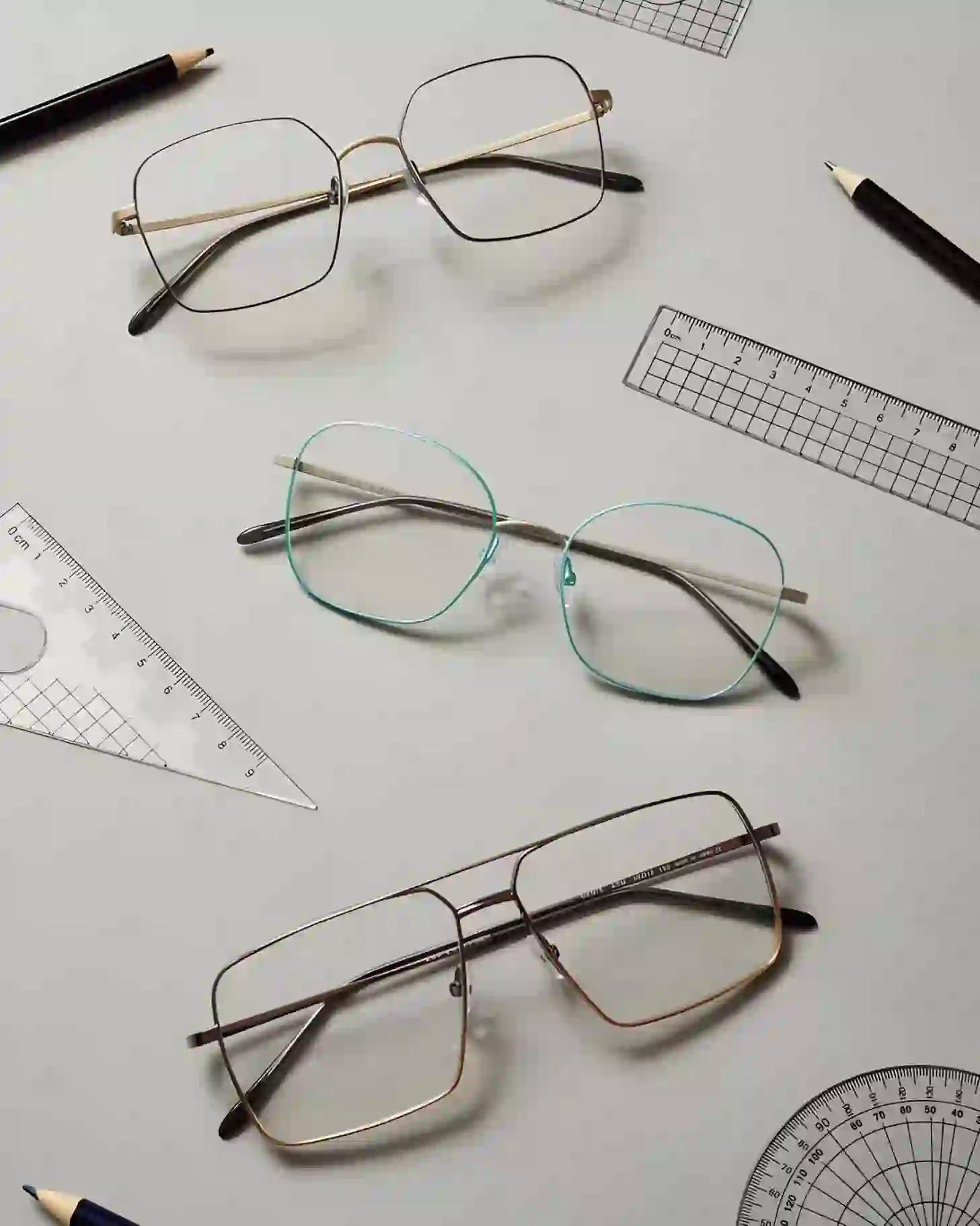

Representative Titanium Sunglasses Projects

Examples shown for reference only.

Ultra-Light Minimal Frame

Developed for maximum comfort with a clean, modern profile.

Structural Titanium Sunglasses

Engineered for enhanced rigidity while maintaining lightweight balance.

Hybrid Titanium Design

Titanium structure combined with complementary materials for performance and style.

Premium Lifestyle Titanium Sunglasses

A refined design built for long-term daily wear.

These examples reflect different structural and aesthetic approaches — many projects begin with similar reference directions.

Comfort Designed for Daily Wear

Lightweight titanium frames reduce pressure on the nose and ears, supporting extended wear during daily and outdoor use.

Balanced geometry and precise fitting help maintain stability and comfort throughout the day.

This level of comfort is especially important for sunglasses intended for all-day or frequent wear.

Balanced weight distribution across the frame

Stable fit during movement and extended use

Durable structure with a refined wearing feel

Customization Options for Titanium Sunglasses

Customize structure, finishing, and brand details to match your collection goals.

- Frame shape and profile

- Temple length and geometry

- Surface finish (matte, brushed, polished)

- Branding elements and signature details

- Packaging and presentation options

Most projects start with only a few defined elements, with details refined progressively during development.

Quality & Compliance Support

Titanium sunglasses are developed with export markets in mind. We support material traceability, structural inspection, and quality processes aligned with international requirements.

QC

Traceability

Durability

Nickel-Safe

UV-Ready Docs

FAQ

These questions often come up during early-stage titanium sunglasses development.

Titanium is not inherently too rigid for sunglasses. When properly engineered, it offers controlled flexibility while maintaining structural stability, making it suitable for comfortable, long-term wear.

Yes. Titanium frames can be customized in terms of geometry, surface finishing, color treatment, and branding details. Customization is usually aligned with your brand positioning and intended wearing experience.

Yes. Titanium offers excellent corrosion resistance, making it suitable for outdoor use, including humid or coastal environments. It also maintains strength and finish stability under frequent temperature and usage changes.

We ensure consistency by controlling key dimensions, documenting all approved iterations, and verifying alignment at each production stage. This helps ensure that mass production accurately reflects the approved sample in fit, finish, and structure.

We support small-batch development depending on frame structure and component selection. Many projects begin at a limited scale and are designed to scale as the collection develops.

Get in Touch

Planning a Titanium Sunglasses Collection?

You don’t need finalized specifications to get started — early concepts or reference designs are enough.

Share your idea, target market, and estimated quantity, and we’ll outline a practical development approach for your titanium sunglasses project.

jenny@sailook.com

+86-13410767035

Address

2F, No. 96, Youtian Garden Rd, Anliang 5th Village, Yuanshan St, Longgang Dist, Shenzhen, China