TR90 SUNGLASSES

Custom TR90 Sunglasses for Performance-Driven Brands

We help brands develop lightweight, flexible TR90 sunglasses — from structure optimization and fit tuning to scalable production.

TR90 Sunglasses, In Plain Terms

TR90 is a high-performance thermoplastic widely used for frames that need to flex, recover, and stay comfortable during long wear.

For sunglasses, it works especially well in sport, outdoor, and everyday active lifestyles where impact and repeated handling are common.

The result is a frame that feels light on the face while remaining resilient in real-world use.

Why Brands Choose TR90 for Sunglasses

Designed for motion

Frames that stay comfortable and stable during movement.

Resilient by nature

Flexes under force and returns to shape for repeatable daily use.

Built for practical programs

Suitable for scalable collections that emphasize comfort and durability.

Why Brands Work with Sailook on TR90 Sunglasses Programs

Engineering-first development

We don't just process TR90 — we engineer for flex zones, recovery behavior, and long-term fit stability.

Brand-level customization

From frame geometry and temple tension to logo placement and surface finish — details are tuned to your brand, not generic molds.

Scalable production planning

We design with MOQ, tooling efficiency, and repeatability in mind — so your first launch can scale without rework.

Transparent development process

Clear technical drawings, revision rounds, and production updates at every stage.

Performance Features That Matter

Lightweight Wearability

Helps reduce long-wear fatigue during outdoor use.

Flex & Recovery

Designed to bend under stress and return toward its original shape.

Impact Tolerance

A practical choice for scenarios where drops and knocks can happen.

Stable Fit Under Movement

Can be tuned for grip and balance to reduce slipping during activity.

TR90 Compared to Other Sunglasses Materials

Material choice should follow the intended use scenario — performance, aesthetics, or structured expression.

| Attribute | TR90 | Acetate | Metal |

|---|---|---|---|

| Primary strength | Flexibility and resilience | Visual richness and feel | Defined structure and lines |

| Weight perception | Light | Medium | Medium |

| Impact tolerance | High | Medium | Medium |

| Best use scenarios | Sport / outdoor / active everyday | Lifestyle / fashion-driven | Fashion / structure-forward |

| Collection positioning | Performance-focused | Mid–Premium lifestyle | Mid fashion & lifestyle |

Fit and Stability for Active Wearing

TR90 frames can be tuned to feel secure without becoming uncomfortable. We focus on balance and tension so the sunglasses remain stable through motion and repeated handling.

- Temple tension tuned for secure wear

- Balanced weight distribution across contact points

- Geometry designed to reduce slipping during movement

- Repeatable opening/closing feel for daily use

Engineering Considerations for TR90 Frames

TR90 performance depends on structural planning, not only material choice. We plan thickness, stress zones, and assembly details to support stable production outcomes.

- Thickness planning to balance strength and flex

- Stress-zone design for repeated bending behavior

- Hinge and connection stability for long-term use

- Assembly alignment checks for consistent fitting

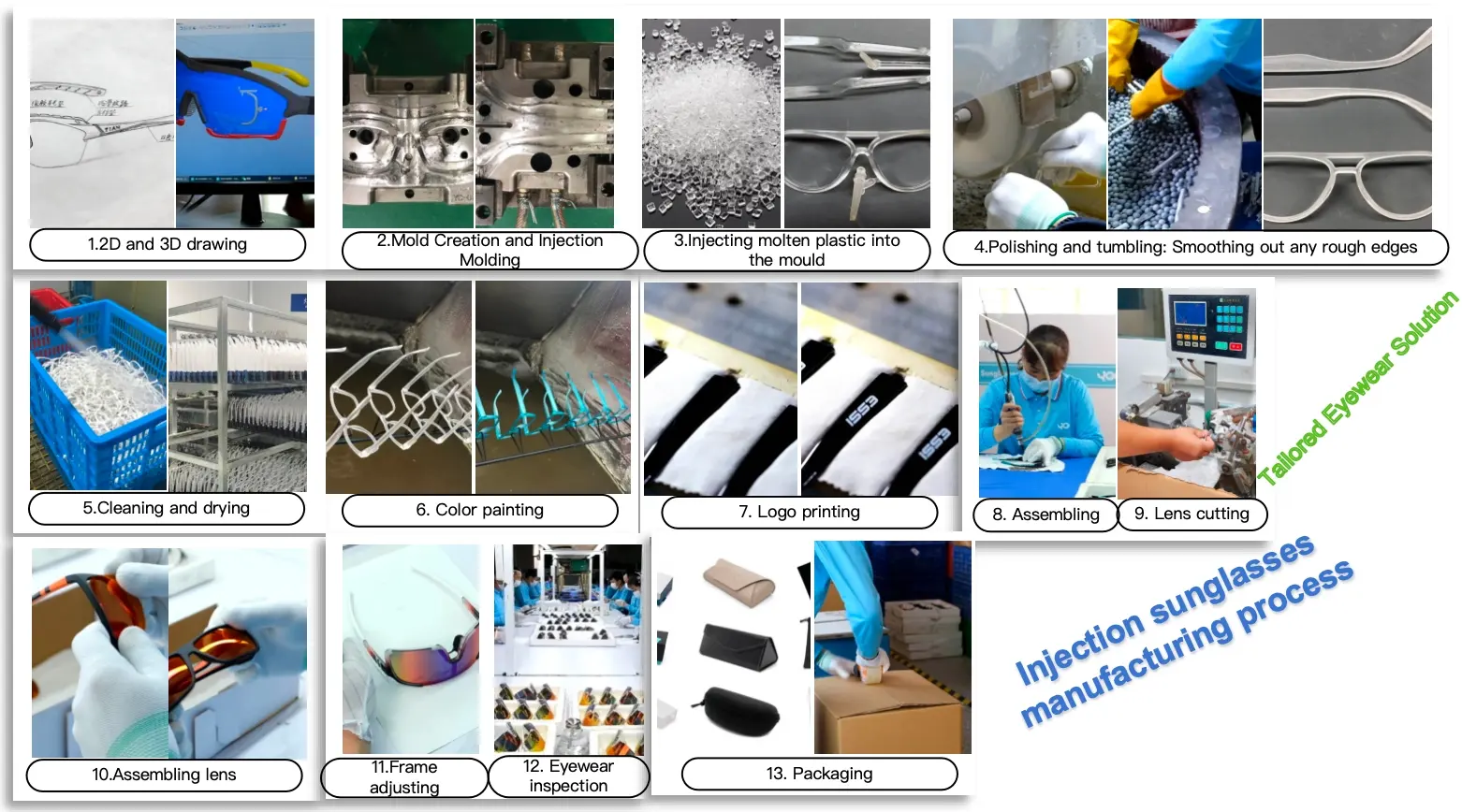

How TR90 Sunglasses Are Produced

Material Conditioning & Preparation

Injection Molding

Trimming and Structure Inspection

Surface Treatment & Texture Options

Assembly and Fit Tuning

Quality Inspection

Process details vary by design, tooling, and finish requirements.

Every step is managed in-house or by long-term partners, with fit, consistency, and repeatability as the priority.

Representative TR90 Sunglasses Concepts

Examples shown for capability reference only.

Sport-Oriented TR90 Sunglasses

Coverage and fit tuned for high movement.

Outdoor Lifestyle TR90 Sunglasses

Balanced comfort and durability for daily outdoor wear.

Lightweight Everyday TR90 Sunglasses

Clean look with a comfort-first structure.

Hybrid TR90 Structure

TR90 combined with complementary components for grip and stability.

How Far Can You Customize a TR90 Frame?

Adapt the frame to match your use scenario, brand direction, and fitting preferences.

- Frame shape and coverage level

- Temple length, curvature, and grip tuning

- Surface texture (smooth, matte, pattern)

- Color options aligned with your palette

- Branding details and signature elements

- Packaging and presentation support

From subtle fit tuning to full structural adjustments, customization happens before tooling — not after problems appear.

Durability for Real-World Handling

TR90 is often selected for programs where frames face drops, packing pressure, and frequent use. We design for resilience and consistent feel over time.

Handling Tolerance

Built for common knocks and daily handling.

Recovery Behavior

Flex under stress with return-to-shape behavior.

Fit Retention

Geometry planned to help maintain stable wear.

Program Reliability

Designed to support repeatable production and long-term supply.

FAQ

Yes. Many TR90 projects begin with sampling before moving into full-scale production. This allows brands to test fit, comfort, and market response with lower upfront risk.

Absolutely. We always evaluate your brand positioning, target market, and use case first. If another material performs or aligns better, we'll recommend that option honestly before production.

Design and thickness planning matter. We plan stress zones to support recovery behavior in daily use.

TR90 emphasizes performance and resilience, while acetate is often chosen for richer aesthetics and feel.

Yes. Shape, coverage, fit tuning, surface texture, and brand details can be developed.

Tooling, design complexity, and finishing requirements are the main factors.

Planning a TR90 Sunglasses Launch?

Tell us your use case, brand positioning, and expected volume — we'll respond with a clear development path.